In high-risk medical device manufacturing, quality serves as a foundational operating principle that defines commercial success and regulatory readiness. Thus, treating Quality Assurance and Regulatory Affairs (QARA) as a downstream function can be a costly mistake for medical device manufacturers. True innovation demands a QARA-centric approach, integrated in the product’s DNA and embedded throughout the manufacturing cycle.

Recent market intelligence reveals a strong link between fragmented QARA processes and costly product recalls. The numbers are staggering: between 2012 and 2022, the U.S. FDA recorded over 26,000 medical device recalls, highlighting the high stakes of non-compliance. As global regulators tighten their scrutiny and new competitors emerge, a medical device’s success no longer hinges on fixing quality issues at the end of the process, but on embedding QARA at every stage of development.

The clear takeaway? To gain regulatory speed and safeguard your product’s success, upstream integration of QARA is essential.

This article explores how a proactive, QARA-centric manufacturing strategy can streamline compliance, minimize risks, and accelerate time-to-market for medical device companies.

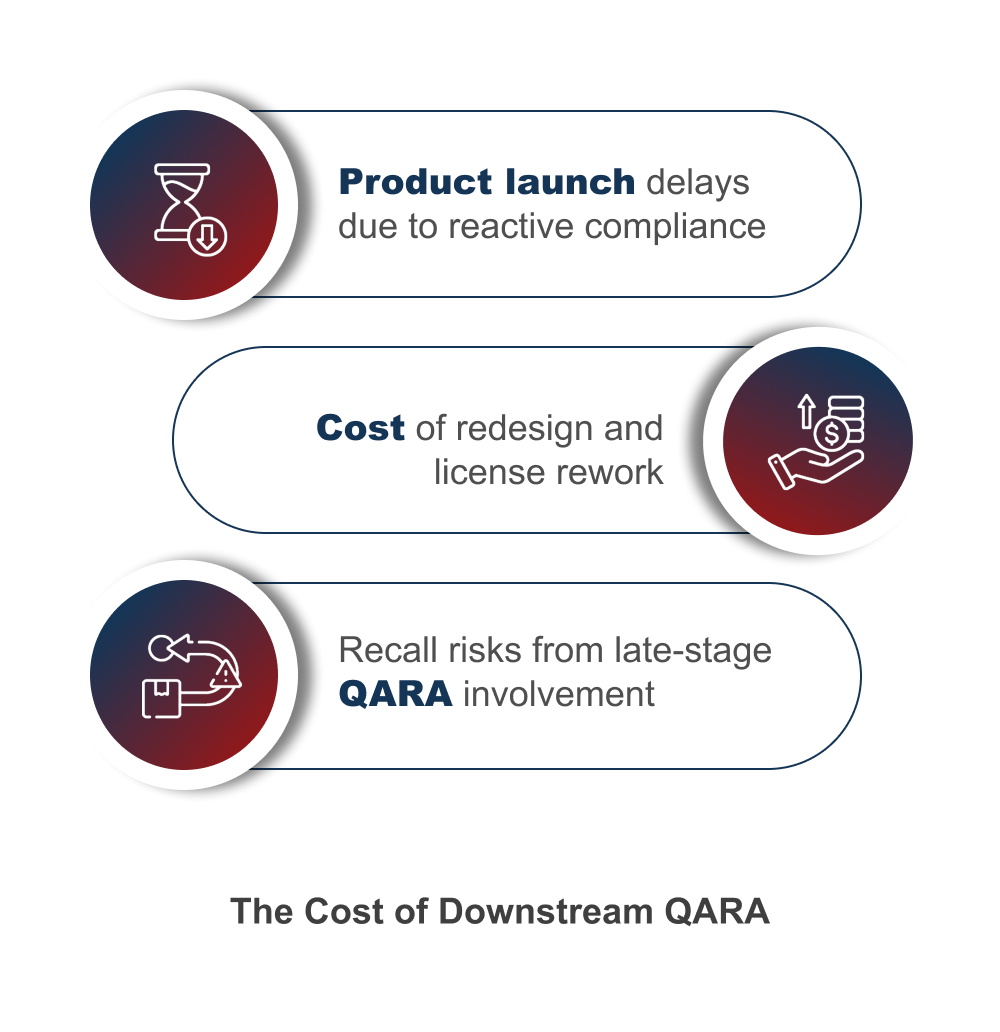

The Hidden Cost of Downstream QARA in Medical Device Manufacturing

Traditionally, Quality Assurance and Regulatory Affairs teams were looped in late, as professionals responsible for documentation, audit prep, and corrective actions. However, this model has repeatedly proven inadequate. When design and manufacturing happen in isolation from QARA, companies pay the price in delayed filings, revalidation exercises, and compliance gaps.

According to a McKinsey & Company report, the medical device industry’s “direct cost of poor quality” ranges between ~$17 billion to $24 billion annually. It further states that spikes in “non-routine compliance costs”, arising from events like recalls and major observations, can add an additional $5 billion per year to this number.

These statistics highlight that poor quality and fragmented compliance systems go beyond being just regulatory risks – they are substantial financial liabilities.

The Solution – Integrating Regulatory Foresight into Manufacturing

Syrma Johari MedTech’s approach exemplifies a QARA-centric manufacturing strategy. We apply a dual lens to design and manufacturing, optimizing performance while embedding compliance into manufacturability (DFM) from the outset. ISO 13485:2016 requirements are operationalized early, with design history files (DHFs) created and maintained throughout development. Our risk management files are living documents, updated with each design iteration and aligned with ISO 14971:2019 standards, supporting both audit readiness and end-to-end traceability.

Simultaneously, our regulatory teams stay closely aligned with global frameworks, from India’s CDSCO Medical Device Rules to US FDA regulations and EU MDR Annexes, ensuring faster regulatory approvals and smoother entry into international markets.

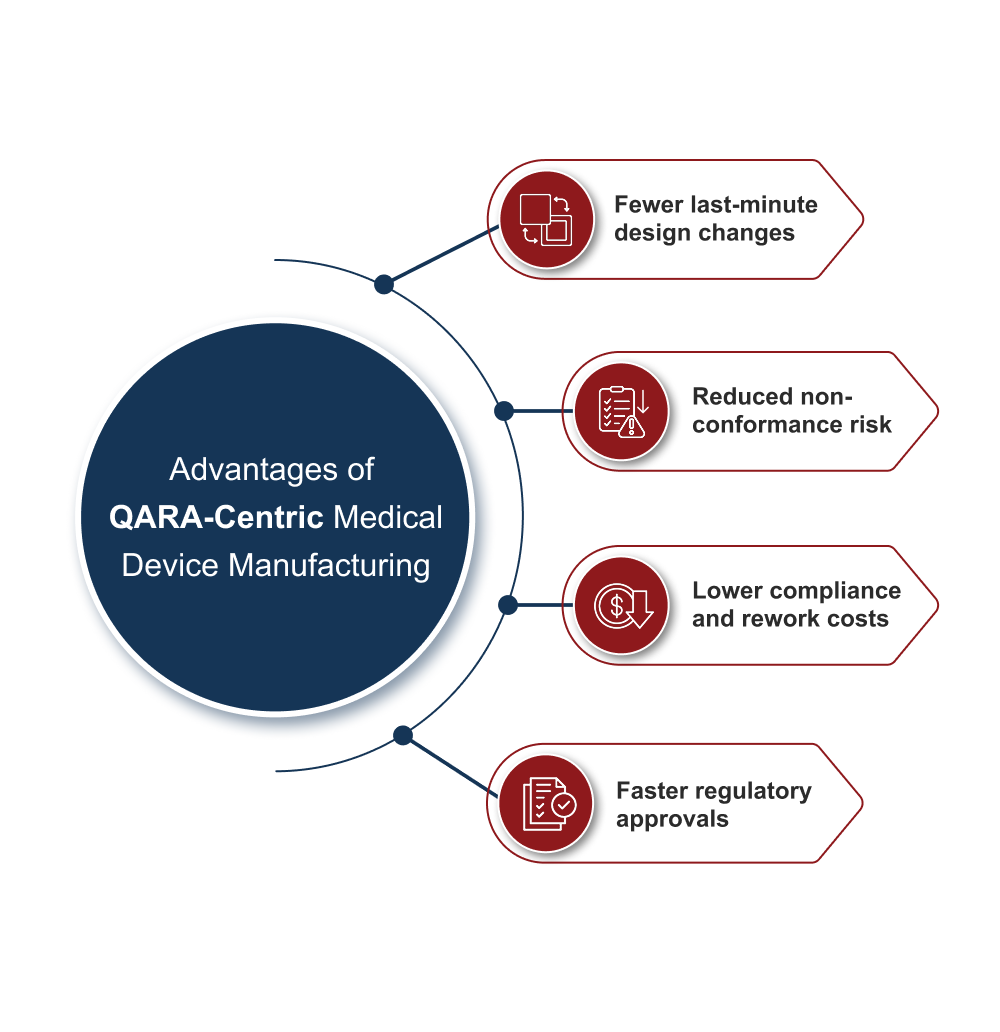

The Advantage: Audit Readiness and Faster Time-to-License

With regulatory compliance built into every manufacturing stage, medical device companies can enter audits with confidence, not panic. The result: fewer last-minute design changes, reduced non-conformance risk, lower compliance and rework costs, and faster regulatory approvals.

Checklist-Driven Compliance: Syrma Johari MedTech’s CDSCO Playbook

To maintain regulatory rigor, we have instituted an internal compliance checklist system modelled after CDSCO’s audit protocol. This includes:

- Live product technical files with traceability to design inputs and outputs

- Comprehensive risk management documentation

- Clinical Evaluation Reports (CERs) prepared well ahead of final trials

- Manufacturing SOPs cross-referenced with Schedule M-III

This checklist drives internal accountability and ensures regulatory expectations are met proactively by medical device manufacturers.

Change Control: Sustaining Compliance at Scale

At commercial scale, compliance complexity intensifies exponentially. Routine modifications to supplier materials or manufacturing processes can inadvertently breach compliance parameters and void regulatory clearances without robust change management frameworks. This risk becomes even more pronounced when entering new international markets, where each region may require specific documentation, risk justification, or conformity assessments.

Syrma Johari MedTech enforces regulatory-aligned change control tied to ISO 13485:2016 Clause 7.3.9. Every engineering change triggers:

- A documented regulatory impact analysis

- Updated risk assessments under ISO 14971:2019

- Cross-functional QARA sign-off before release

This disciplined approach ensures that our partners remain globally audit-ready while scaling or expanding into new geographies.

Conclusion – QARA is a Value Centre and Growth Enabler

At Syrma Johari MedTech, we prioritize QARA as a business accelerator, and not a mere audit function. Embedded across the manufacturing lifecycle, it becomes a competitive advantage: enabling faster market entry, lower compliance costs, and stronger regulatory trust.

This advantage compounds across every stage of the product journey—whether it’s refining medical device quality plans, streamlining design for manufacturing, or building audit resilience. The future belongs to medical device companies that treat QARA as a core operating principle.

Ready to scale your medical device with a winning regulatory strategy?

Partner with us to make quality and regulatory compliance the foundation of your growth!